CHAPTER FOUR

Tool Basics

Having a variety of pliers, cutters, and wireworking tools is essential for any jewelry maker’s toolbox. Good tools, proper technique, and lots of practice help produce professional results. Each tool has a specific purpose. The three basic tools — round nose pliers, chain nose pliers, and side cutters — can be supplemented with other wireworking, metalworking, and shaping tools. In addition, a measuring tape, caliper, and a variety of storage containers are extremely useful.

Pliers and Cutters

Pliers and cutters designed for wireworking are manufactured in several qualities from beginner tools, usually made in Pakistan, to intermediate tools made in Germany, to advanced tools made in Spain or the United States. The quality of these pliers and cutters varies by the type of metal they are made from to the way the tool is crafted. Spring-loaded models of tools are easier to manipulate.

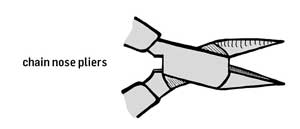

Chain nose pliers are beading pliers with a tapered jaw that is rounded on the outside and flat and smooth on the inside. This wireworking tool is commonly used for crimping and gripping wire.

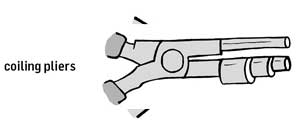

Coiling pliers are useful for quickly and easily making uniformly shaped rings, clasps, ear wires, or other findings. These pliers come with jaws of differing diameters from as small as 2 to 5 millimeters to as large as 13 to 20 millimeters.

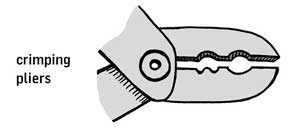

Crimping pliers are used for crimping tube-shaped crimp beads into neat, folded, flat crimps. This tool is absolutely essential!

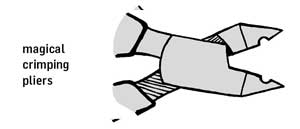

Magical crimping pliers are specialty pliers used to transform 2×2 tube crimps into small round beads.

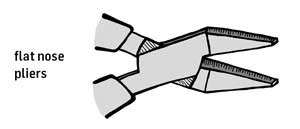

Flat nose pliers are beading pliers with a tapered jaw that is smooth and flat on both sides. This tool is useful for projects that require a larger gripping surface or for making chain maille.

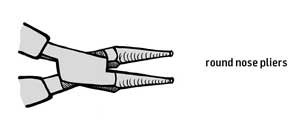

Round nose pliers are beading pliers with smooth, conical barrels that are ideal for making loops. This beading tool is essential for making earrings or any wirework projects that have loops or curves. They are also useful for opening and closing bead tips. Round nose pliers should not be used for gripping.

Split ring pliers are specialty pliers with a small “tooth” on one jaw that will hold open a split ring so that a charm or another ring can be fed onto an existing ring. This tool is especially useful for projects that employ lots of split rings, like charm bracelets.

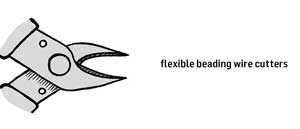

Flexible beading wire cutters are flush cutters that easily snip through the nylon and metal layers of flexible beading wire. These cutters have small tips for precise cutting of delicate wires.

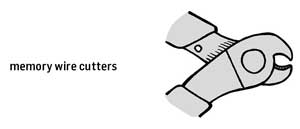

Memory wire cutters are heavy-duty cutters designed specifically for cutting hard steel memory wire. This specialty tool should always be used to cut memory wire. The blades of other cutting tools are easily damaged when attempting to cut memory wire.

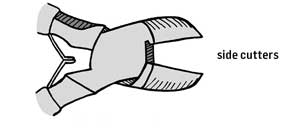

Side cutter, sometimes called a flush cutter, is an essential beading tool. A side cutter is used to cut hard wire. The blades of a side cutter have a notched side and a flat side that allow for a close cut on small projects.

Wire-Shaping Tools

Tools for shaping wire are remarkably useful. Wire-shaping tools are available to twist, coil, curl, flatten, and texture wire.

A ball-peen hammer is used to flatten and harden wire and wire shapes. The head is rounded on one end and flat on the other and is usually made of heat-forged steel for strength.

A chasing hammer has a forged steel head that is mounted on a wooden handle. One side of the head has a large face for flattening; the other is a ball-peen side for creating a hammered look.

A mallet has a head made of wood or rubber fastened to a wooden handle. Mallets deliver a softer blow than a metal-headed hammer.

A bench block is a flat steel plate that provides the necessary surface for flattening and hardening wire and wire shapes with wireworking hammers.

A wire jig is an amazing tool that aids in the shaping of the wire into consistent and even coils, curls, and swirls. To create wire shapes, small pegs are inserted in an evenly spaced grid of holes in a metal or acrylic plate. The wire is wrapped around these pegs in interesting patterns. The shapes are then removed from the jig and hammered to flatten and harden the wire.

Measuring, Polishing, and Storage

In addition to the tools mentioned previously, wire-working requires a few other tools that make it easier to complete a full range of projects. While not all of these tools are critical, some techniques are not possible without specific implements.

Measuring Tools

Measuring tools are vitally important. Once beads, findings, and pieces of wire have made their way to storage containers and are no longer labeled with a size, the only way to determine the size is by measuring them individually. Making jewelry also requires knowing a person’s ring size, necklace length, or wrist dimension. There are all sorts of measuring tools available to make the job easier.

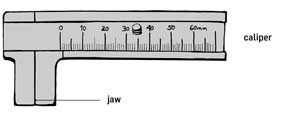

Calipers are small metal devices with a sliding jaw that makes measuring beads and bead holes very easy. To use a caliper, slide open the jaw, place the bead in the jaw, slide the jaw closed again, and then refer to the measurement guide to determine the size of the bead.

A ring mandrel is a tapered rod of steel or acrylic used to form, shape, and measure the correct finger size when making a ring. Ring mandrels are usually measured out in quarter ring sizes from 1 to 16.

A measuring tape marked in both inches and centimeters is an important and useful tool to always have on hand. Beads are made and sold in millimeter dimensions, but jewelry is frequently made in inches. Having a tape measure handy makes the conversion so much easier.

A wire gauge is a useful tool for easily determining the diameter or thickness of a piece of wire. By running a wire through the various openings, it is possible to figure out the wire’s gauge even if the wire is no longer in a marked package.

Polishing Products

Polishing products are important for preventing or repairing the effects of tarnishing or oxidization. Most metals will tarnish, oxidize, or darken with time and exposure to air. Metal cleaning and polishing products should always be used with caution and with proper protection for yourself and your surroundings. Regular cleaning and polishing, as well as proper storage, are the best ways to keep metal jewelry looking its best.

Antitarnish paper is a wonderful product for preventing metal jewelry from tarnishing or oxidizing while pieces are being stored. Add little pieces of anti-tarnish paper to the bottom of storage containers for the best results.

Jeweler’s rouge is a cloth impregnated with a professional compound that cleans and removes tarnish from gold, silver, and other metals. A polishing cloth is then used to buff the metal to a high sheen.

Polishing cloths are easy-to-use, chemically impregnated fabric sheets that remove tarnish or oxidization and polish silver, gold, brass, and copper to their original luster.

The silver dip is a liquid, chemical tarnish remover. Dip or wipe silver to remove tarnish, wash the metal with soap and water, and polish it dry for the best results.

Storage Containers

Storage containers for beads, findings, and tools are not only useful but they protect the materials, keep tools clean and sharp, and keep everything organized. A wide range of containers from screw-top stacking jars to flat, compartmentalized boxes are available. Metals are best stored away from light and in airtight containers.

You can read the previous entry (Chapter Three) in the series here. You can see the next entry (Chapter Five) in the series here.