Beaded Jewelry – Wirework Techniques: Skills, Tools, and Materials for Making Handcrafted Jewelry.

Introduction

Metal is the foundation material for making wire, chain, and jewelry-making findings. Humans have been using metals in some way or another since the beginning of civilization. As long ago as 6000 BCE, the Egyptians, followed by the Greeks and Romans, were making decorative objects and jewelry from gold. A basic understanding of metallurgy, the science of working and shaping metal, is useful for anyone interested in creating jewelry with these materials.

Metals are either elements or alloys. Elements are the basic building blocks of chemistry; metal elements are unique because they reflect light, are malleable, can be fused, and conduct heat and electricity. Naturally occurring metal elements in their pure form are generally not very useful because they are too soft, too hard, or too brittle. To be useful for jewelry making, metal elements with different qualities are combined to make more useful metal alloys.

Wire, chain, and jewelry-making findings come in a wide range of metals, gauges, and styles. A little assistance when shopping for wire and metal products can go a long way. Local bead shops, staffed by knowledgeable jewelry makers, are usually an excellent resource. Some alloys may contain metals that are known to cause allergies or to be carcinogenic, so shopping in person is always the best way to ensure that you get what you expect!

Carson, Rachael, and Kate

A Word about Lead

Lead is worth mentioning in any discussion about jewelry metals. Traditionally, lead has been used as an ingredient in a number of alloys, as it makes an alloy more malleable and lowers its melting temperature. Today lead is known to contribute to a variety of health problems. State and local governments have begun to regulate the amount of lead permitted in products, especially jewelry products that may be handled by children. To date, California is the only state that also regulates lead content in adult jewelry.

CHAPTER ONE

Wire Basics

A wire is metal that has been stretched into long, thin, flexible filaments. It is an incredibly versatile material with a multitude of applications. A wire can be used to make structures, to link elements together, and to add decorative interest. Many types of wire are available in a full range of metals, sizes, shapes, and finishes, perfect for all kinds of jewelry-making projects.

Wire Types

When people begin making wire-based jewelry and findings, the question of wire type always arises. The kind of project being made and personal preference are generally the deciding factors. There are two types of wire used in jewelry making: flexible beading wire, which is used exclusively for stringing beads, and hard wire, which is used for wireworking. Each type of wire comes in a variety of diameters or gauges and colors; hard wire also comes in a variety of shapes.

Flexible Beading Wire

Flexible beading wire is one of the most popular materials used for stringing beaded jewelry. This strong but flexible, nylon-coated, stainless steel wire is secured to a clasp with crimp beads. Two popular brands of flexible beading wire are SoftFlex and Beadalon. These brands offer the highest-quality choices in a variety of diameters, flexibilities, and colors. In addition to the standard silver, gold, and metal colors, flexible beading wire comes in a range of seasonal colors, as well as black and white.

When selecting a flexible beading wire for a stringing project, it is best to select the thickest one that will comfortably fit through the beads being used. Different diameters of flexible beading wire are recommended for different sizes and weights of beads.

Very fine diameter (.010 to .013 inch) is best used with tiny, lightweight beads, gemstones, or pearls with very small drill holes. This diameter wire drapes nicely as long as the beads being used are light enough.

Fine diameter (.014 to .015 inch) is recommended for general-purpose stringing projects using light- to medium-weight beads. Seed beads, crystals, and Czech glass beads string and drape nicely on this diameter wire. Avoid using heavy beads with this diameter beading wire, as excess weight can pull the wire out of the crimps and lead to a loss.

Medium diameter (.018 to .019 inch) is recommended for medium-weight beads, large glass beads, or stone beads, as well as for projects that need extra durability. This diameter of beading wire is very popular for bracelet and necklace projects that are worn frequently or that are made with larger or heavier beads.

Heavy diameter (.024 inch) is suggested for projects that get a lot of use, such as bracelets, lanyards, and eyeglass holders. This diameter wire works well with very large or heavy beads, including lampwork beads, African trade beads, and beads made from bone and stone. It is also appropriate for beads with large holes or holes that may be rough or abrasive.

Another variable to consider when selecting a flexible beading wire is the number of strands of stainless steel from which a particular beading wire is made. The more strands this type of wire is made from, the sturdier and more flexible it will be. Beadalon produces a good-quality wire made with only seven strands of stainless steel. This wire is the least flexible option but is ideal for craft projects or children’s jewelry.

Both SoftFlex and Beadalon produce better-quality beading wires made with 19 or 21 strands of stainless steel. These beading wires are stronger and more flexible than 7-strand beading wire. Both brands of 19- and 21-strand beading wire are popular and cost-effective for general purpose bead stringing, and they drape nicely when used with appropriately sized beads. The best-quality beading wires that SoftFlex and Beadalon produce are made with 49 strands of stainless steel. These beading wires are by far the strongest and most flexible and withstand the most wear. They are highly recommended for working with valuable beads.

Hard Wire

Hardwire is the type of wire used for making wire-based jewelry and findings. It is most commonly used for wire wrapping, creating a linked chain, and making wire-based findings. Hardwire is an amazing material to work with because it is fluid yet sturdy, soft yet hard, and creates a lovely finished product.

There are three types of hard wire used in wireworking: precious metal wire, base metal wire, and memory wire. It is important to consider the attributes of each type of hard wire when selecting one to work with. Things to consider include material (metal type), temper (hardness), diameter (gauge), and shape. The following pages explore these attributes. For a descriptive list of metal types, see the appendix.

Precious Metal Wires

Precious metal wires produce both beautiful and valuable pieces of jewelry. These wires may be the most expensive, but they produce the best results and should always be used when making heirloom or keepsake jewelry. Karat gold and fine or sterling silver are the most popular precious metal wires for making wire jewelry and components. Each type of precious metal wire comes in a range of tempers, gauges, and shapes.

- Karat gold wire is the most expensive wire available and is often hard to source. The term karat refers to the percentage of pure gold found in various gold alloys and is designated with a “K” after the percentage. The color and value of gold wire depend on its gold content. Gold wire is most often available in 24K, 18K, and 14K gold. For a comparison of karat weight for a variety of gold alloys, see the appendix.

- Gold-filled wire, also known as rolled gold wire, is made by permanently bonding a 14- or 18-karat gold layer to a solid brass or copper core and then drawing it through a series of draw plates to the desired gauge. Gold-filled wire is popular because it is more affordable than karat gold wire and is essentially the same color because of the gold content. Since the gold-filled wire is made with a lot more gold than gold-plated wire, it tends to be more flexible and certainly more durable. For a product to be labeled as gold-filled, it must contain a minimum of 1/ 20 pure gold by overall weight.

- Rose gold wire is made from an alloy of gold, copper, and, depending on the color, a small percentage of fine silver. The addition of copper to the alloy gives rose gold its warm, rosy tone. The greater the copper content the redder the coloration of the alloy. Typical 18-karat rose gold wire is made of 75 percent gold, 22.25 percent copper, and 2.75 percent fine silver.

- The white gold wire is made from an alloy of gold and silver metal, usually palladium. A common 18-karat white gold is made from an alloy of 75 percent gold and 25 percent palladium. The addition of palladium makes for a softer, more pliable metal alloy, ideal for wire and findings. For sturdier or heavier gauge items like rings and pins, nickel is added to the alloy in place of the palladium. If you suffer from a nickel allergy, it is always good to ask about the nickel content of white gold wire or findings before purchasing them.

- The fine silver wire is not an alloy like sterling silver. It is 99.9 percent pure silver with the balance being made up of trace impurities. Fine silver is generally too soft for making functional objects, but it makes a wonderfully fluid wire that can easily be work-hardened. Because fine silver does not contain any copper, it will not oxidize or blacken when heated. This quality makes fine silver ideal for fusing and annealing if it is work-hardened too much.

- Sterling silver wire is made from an alloy of 92.5 percent pure silver and 7.5 percent copper. It is one of the most popular wires for wire wrapping, making a linked chain, and for making wire-based findings. Due to its popularity, an abundance of ready-made clasps and earring findings is available to complement any wiring project. Sterling silver is exceptionally easy to work with, is consistent in color, and comes in a wide range of gauges, tempers, and shapes.

- Argentium wire is made from a modern sterling silver alloy that contains 93.5 percent pure silver and 6.5 percent copper and germanium. Since the alloy contains 93.5 percent pure silver, it meets the legal standard to be marked as sterling silver. Argentium is bright white in color and looks more like fine silver than traditional sterling. The tiny percentage of germanium gives this alloy an increased natural tarnish resistance.

- The silver-filled wire has a solid copper or brass alloy core bonded with a layer of sterling silver. A silver-filled wire is more durable than silver-plated wire because the bonded layer of sterling silver is much thicker. The bonded layer does not wear off with use as the layer of silver on silver-plated wire tends to. A silver-filled wire is a great-looking and cost-effective alternative to sterling silver wire.

Base Metal Wires

Base metal wires are most often plated, colored, or coated, although raw copper and raw brass wires are also available. These wires are cost-effective alternatives to precious metal wires.

“Plated” is a term that means different things to different people. Plated wire generally refers to a base metal wire that has been electroplated with another metal. Craft wire is often mistakenly referred to as plated wire. Craft wire is actually a base metal or aluminum wire that has been coated, colored, or finished, rather than electroplated.

Base metal wires are a versatile option for jewelry and craft projects since they come in a nice range of qualities, colors, and finishes. There are three main types of base metal wire: German-style plated wire, raw wire, and craft wire.

Tech Tip

Base metal wires are practical for practicing wirework. One rule of thumb is to practice twice using base metal wire before making a final piece in a precious metal wire.

German wire

German wire is the best-quality plated base metal wire available. German beading wires have an anti-tarnish coating and are the perfect temper for most wire-wrapping projects. The highest-quality German beading wires are made in Germany. Lower-quality German-style beading wires are made in the United States. Both German and German-style wires come in a range of tempers, gauges, and fancy shapes.

- Copper and brass German wires have a copper or brass-alloy core that is finished with an anti-tarnish coating. These wires are not electroplated or colored.

- Silver and gold German wires are made with a copper core that is electroplated with precious metal and finished with an anti-tarnish coating. Gold German wire is plated with 14-karat gold, and silver German wire is plated with sterling silver. These wires provide the closest color match to their precious metal counterparts.

Raw wire

The raw wire is solid copper or brass-alloy wire that is not plated or coated with an anti-tarnish finish. Because the raw metal wire is uncoated, it tends to oxidize and darken very quickly.

- The raw copper wire is a very malleable wire that is perfect for beginners. It is easy to work with, great to practice on, and very cost-effective. Freshly polished raw copper has a warm, red-brown luster. As copper wire ages and oxidizes, it takes on a soft green patina.

- The raw brass wire is made from an alloy of copper and zinc that is similar in color to gold, especially after being freshly polished. Brass wire is less expensive than gold wire and easy to work with. It is a versatile wire that is good to practice with but will darken as it oxidizes.

Craft wires

Craft wires are the least expensive wires available and are produced by several manufacturers. Each brand varies in flexibility, metal content, and coating process. The proprietary coloring processes of these wires vary by manufacturer. Each brand of craft wire offers a nice range of both natural and seasonal colors in a range of gauges. Choosing a craft wire to work with is primarily a matter of personal preference.

- Artistic Wire is a popular brand of permanently colored copper wire. The proprietary enamel-coating process resists tarnishing, peeling, and chipping. Artistic Wire is flexible and easy to work with, making it a wonderful choice for children’s jewelry and craft projects. It comes in 13 gauges and in silver, brass, and copper, as well as a wide range of seasonal colors.

- Craft Wire, manufactured in the United States by BeadSmith, is available in a nice range of colors to coordinate with just about every metal hue. This brand of craft wire is stiffer than others but is similar in flexibility to a half-hard wire. Craft Wire is very bright and shiny, and the tarnish-resistant coating helps to maintain the bright coloration over time.

- Parawire is made with a 99 percent copper core, and the company’s exclusive coloring process produces the brightest colors of craft wire available. After being colored, the wires are coated with nylon for a durable finish. Parawire is softer than Craft Wire but harder than Artistic Wire.

- SoftFlex craft wire is a permanently colored copper wire that is resistant to scratching, peeling, and marring. This brand of wire is 100 percent free of lead and nickel and is colored using a special enameling process. All SoftFlex craft wires, except for bare copper, are clear-coated to prevent tarnishing.

Memory Wire

Memory wire is a unique steel wire material. It is made from tempered spring steel that always returns to its coil form when expanded and released. It is manufactured in a ring, bracelet, and necklace diameters and is packaged in coils. Memory wire comes in several colors including silver, gold, and bronze; in around and flat wire shape; and in a round and oval coil.

Wire Attributes

A wire has a variety of attributes that make it fun to work with. Each gauge (size) of wire is available in a range of shapes and tempers (hardness). Many types of wire have two particularly appealing attributes: they can be hardened by working with them or softened by heating them.

Wire Gauge

Wire gauge refers to the diameter of a round wire or the cross-sectional dimension of shaped wire. Drawing is the process of pulling a wire through one or more successively smaller dies on a draw plate to produce the gauge of a wire. As a wire is drawn, the temper (hardness) of the wire increases as well. A wire can be returned to a softer state by a heat process called annealing. This process allows wires to be manufactured in a wide range of gauges of varying tempers. The machine-made wire is annealed as it is drawn and coiled.

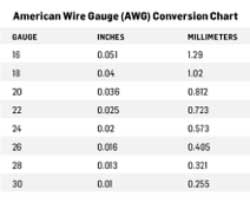

The gauge of a wire is defined by the number of times it is pulled through the draw plate or dies. Unlike most systems of measurement, the higher the gauge number, the thinner the wire. A very fine 30-gauge wire requires far more passes through the draw plate than a heavy 16-gauge wire.

Several gauging systems are used around the world. The American Wire Gauge (AWG) system has been used in the United States since 1857. This conversion chart shows both the inch and millimeter diameters associated with common wire gauges used in jewelry making.

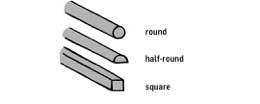

Wire Shape

The wire is manufactured in several shapes, including round, half-round, and square. These shapes are produced when a wire is drawn through a shaped die on a draw plate. Using different wire shapes can produce pretty jewelry and combining shapes can add interest to any wirework project.

Round wire is the most common shape for wire and can be used for almost any wirework project. Round wire is used for making most basic earring findings, including ear wires, head pins, and eye pins. It is also terrific for wrapping beads and for making jump rings and simple clasps.

The half-round wire is flat on one side and domed on the other. It is often used for wire wrapping, linking, and making rings and components. This low-profile style of wire is also used to bind bundles of square wire together in complex designs. The flat side of the half-round wire is placed against the side of a square wire so that the rounded side remains exposed in the finished design. This technique is called banding.

The square wire gives jewelry a completely different look and is frequently chosen for purely aesthetic reasons. The flat sides of square wire lie flush against one another in a way that round wire does not. The squared edges add unique interest to finished pieces of jewelry.

The twisted or fancy wire is primarily used to add textural interest to wireworking. It can be purchased ready-made or can be handmade by twisting round or square wires together with a wire-twisting tool.

Wire Temper

Wire temper describes the hardness or softness of a particular wire: its malleability, its ability to bend fluidly, and its tendency to hold a shape once bent. Wire temper can range from dead-soft (which bends with no resistance) to spring-hard (which is very resistant to bending). As wire or other types of metal are wrapped, hammered, or otherwise manipulated, they gradually become harder; this is called work-hardening. If a wire becomes too hard, it can be softened by annealing. Using a small butane torch to anneal wire is a common metalworking technique.

It is important to purchase wire with the proper hardness for each individual project. Dead-soft or soft wire is ideal for soft bending or making coils or fluid shapes. Half-hard wire is the best choice for making sharp corners or for wrapping stones or beads. A full-hard wire is very stiff and challenging to work with but produces the sturdiest results.

Dead-soft and soft (1⁄4 hard) wires are very malleable and can be work-hardened very easily. Be careful not to overwork dead-soft or soft wires as they can become brittle and excessively springy.

Half-hard wire is harder than soft wire but is still very manageable to work with. Half-hard wire, even in narrow gauges, feels sturdy and holds its shape after being worked.

Tech Tip

It can be helpful to use nylon-coated tools with heavier gauges of half-hard wire to prevent marring the surface of the wire. Both nylon-jaw tools and rubber tips that are used to coat the jaws of wireworking tools are available.

A full-hard wire is harder than half-hard wire and more difficult to manipulate. It tends to be very stiff and can be hard on the fingers. The full-hard wire is unforgiving if you make a mistake. Once the hard wire is bent or shaped it can no longer be straightened.

Spring-hard wire has been tempered so that it will always spring back to its original coil form. Spring-hard wire is very difficult to work with and requires the use of specialized pliers and cutters. Memory wire is a good example of spring-hard wire.

Selecting Wire for a Project

Although wire selection is largely a matter of personal preference, the choice should be guided by some basic rules of thumb. First and foremost, select a wire in the material that suits the components being used in a particular project. For example, if you are using precious metal findings and clasps for your project, use precious metal wire as well.

Choosing a Material

Precious metal wires such as fine silver, sterling silver, Argentium, silver-filled, karat gold, and gold-filled wire are suitable for almost any wirework project. For the most professional look, always coordinate the selected precious metal wire with findings and clasps of the same metal. Be certain to match the metal color as closely as possible, especially when working with gold. The precious metal wire is always the best choice for making heirloom-quality jewelry.

Base metal wires are ideal for a wide variety of jewelry and craft projects. Base metal wires are available in silver-plated and gold-plated copper, raw and coated copper, brass, nickel silver, aluminum, and niobium. Base metal wires are also an excellent choice for practicing wirework techniques and for creating prototypes of jewelry that will eventually be made from precious metal wire.

Craft wires are relatively inexpensive, making them perfect for craft projects, children’s jewelry, and other types of beginner jewelry. Craft wires are available in standard silver, brass, bronze, copper, and black colors. Each brand produces an assortment of brightly colored wires in a range of gauges.

Memory wire is a unique spring-hard wire that returns to its coiled shape when stretched and released. Due to this property, memory wire is ideal for stringing beads to make choker-style necklaces and multi-coil bracelets and rings.

Choosing a Gauge

It is also important to consider the size of your bead holes. Always select the wire gauge that matches the smallest bead hole in your project.

14-gauge and 16-gauge wire are ideal for hammering projects. These gauges are common choices for making heavier clasps, jump rings, eye pins for large-holed beads, frames, wire shapes, and bangles.

18-gauge and 20-gauge wire are suitable for wireworking with larger beads. These gauges are a common choice for wire wrapping, and for making ear wires, head pins and eye pins, clasps, and jump rings. Most people use 20-gauge wire when making their own findings.

22-gauge and 24-gauge wire are great for most jewelry projects and will fit through most beads, including gemstones and pearls. These gauges are commonly used for wire linking and wire wrapping.

26-gauge and 28-gauge wire are used for delicate projects such as knitting or crocheting with wire, wrapping small gemstones, and linking gemstones and pearls. These gauges are also good for working with pearls that have very small holes.

30-gauge wire is essential for projects involving diamonds or semiprecious gemstone beads that have irregular or tiny holes. This gauge is also essential for making intricately woven wire designs.

Choosing a Temper

Selection of wire temper and wire shape should be based on project type and personal preference.

Dead-soft and soft wire are useful choices if the wire will be worked a lot (hammering, bending, and so on) before it is made into a finished piece. Dead-soft wire in a thin gauge behaves more like a fiber than a wire, making it very useful for knitting, crocheting, weaving, and coiling.

Half-hard wire is sturdy and will hold a shape. This popular wire temper is most commonly used for wire wrapping and for making ear wires, head pins, hoops, and clasps.

A full-hard wire is a less common choice because it is more difficult to work with. It is popular with experienced jewelry makers because it stands up to use longer than half-hard wire. It can be used to create clasps, ear wires, head pins, eye pins, and links or components.

Spring-hard wire, more commonly called memory wire, is used to make rings, bracelets, and necklaces that will always hold a circular or oval shape.

How Wire Is Sold

By weight: Karat gold wire is sold by the pennyweight, while gold-filled, sterling silver and silver-filled wire are sold by the ounce.

By the roll: Craft wires are sold on spools of varying yardages, depending on the gauge and brand of the wire.

By the coil: German-style plated wire and raw wire are sold in coils of varying yardages, depending on the gauge of the wire. Memory wire, also available by the coil, is sold by numbers of revolutions.

By the foot: Precious metal and German-style plated wire are sold by prepackaged weight. Bead stores frequently sell these wires by the foot, and sometimes even by the inch.

You can see the next entry (Chapter Two) in the series here.

Fashion Bracelets

Fashion Bracelets